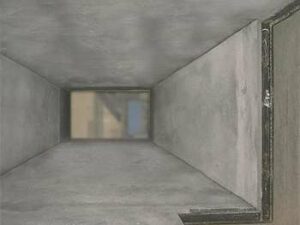

KALCRET ANX eignet sich für die Auskleidung von vielerlei Anlagenkomponenten u.a. von Zyklonen, Bunker, Rutschen, Schurren, Sichter, Silos, Rohrleitungen, Rinnen und Kanälen.

Der besondere Vorteil von KALCRET ANX ist die einfache Handhabung und die Flexibilität in der Praxis. Große und geometrisch schwierige Flächen werden schnell und sicher beschichtet. Die Belastbarkeit ist bereits nach 24 Stunden möglich und die Anlage kann nach kurzer Zeit wieder in Betrieb genommen werden.

Hartstoffkompound KALCRET ANX ist in Gebinden zu 25 kg erhältlich und kann als Spachtelmasse auf Armierung verarbeitet werden. Zusätzlich zur Sackware sind Auskleidungen mit KALCRET ANX auch als vorgefertigte Formteile lieferbar.