Everywhere that massive material flow causes abrasion or impact wear, wear-resistant materials help safeguard productivity and keep processes in motion.

Research findings of AC2T have established that the combination of ceramic elements with rubber support provides innovative options for new applications. Rubber-ceramic hybrid plates withstand extremely harsh impact wear. Though ceramic elements outperform metal abrasion protection in many respects, they are significantly more brittle and fracture more easily under impact loading.

Together with Kalenborn, more effective wear protection and new application areas for ceramics are at the forefront of process development in heavy industry. Researchers are working particularly hard on solutions for voestalpine’s steel division. The approach selected for this project work consists of supporting brittle ceramics with a layer of rubber. With its ability to deform, very elastic rubber can absorb high impact energy in the event of frontal shock, thereby protecting correctly arranged ceramic from fracture.

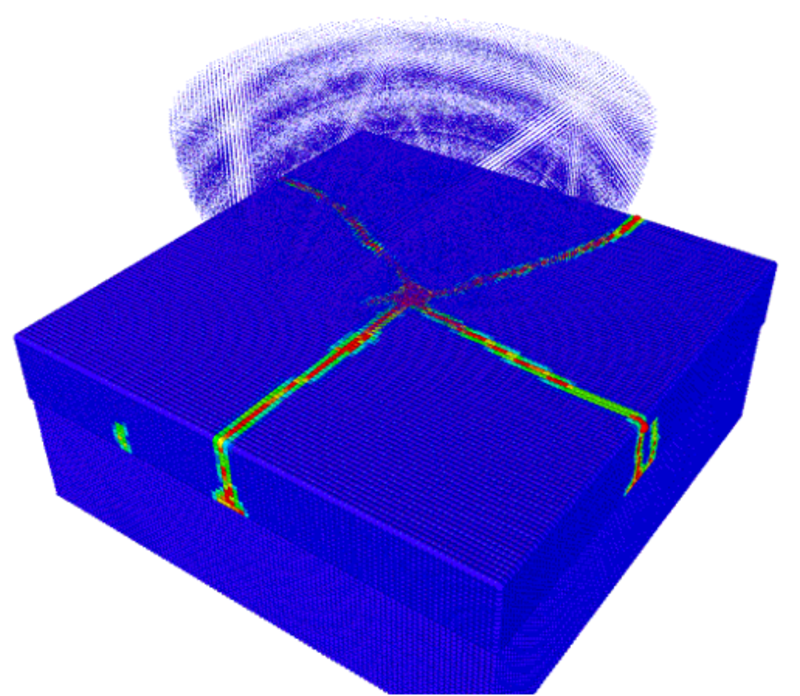

Subsequent scientific studies concentrated on the optimisation of individual components. Accordingly, the composition, shape and thickness of the ceramic components can significantly affect wear resistance, as does the hardness and thickness of the rubber layer as well, of course. To that end, project partners helped conduct experimental trials that replicated an extremely wide range of operating conditions. In addition, computer-aided simulations were used to calculate parameter variations that could not be assessed by experimental means. The findings were unequivocal: For special applications, the optimisation of complete tribological systems made it possible to raise impact resistance by more than ten-fold.

Greatly enhanced efficiency and significantly extended service life have been achieved as a result. In view of this, and given the broad relevance of the topic for heavy industry, this technical solution offers tremendous potential for extraordinarily demanding applications-based configurations.