- Products

- High performance concrete KALCRET

- Fused cast basalt ABRESIST

- Zirconium corundum ceramics KALCOR

- High alumina ceramics KALOCER

- Silicon carbide ceramics KALSICA

- Hard ceramics KALCERAM

- Epoxy-bonded hardcompound KALPOXY

- Composite construction of hard material and rubber KALIMPACT

- Hard casting KALCAST

- Hard overlay welding KALMETALL

- Slide promotion plastics KALEN

- Sprayable Polyurea KALEA

- Applications

- Service

- Company

- Career

- Contact

From the beginnings till now

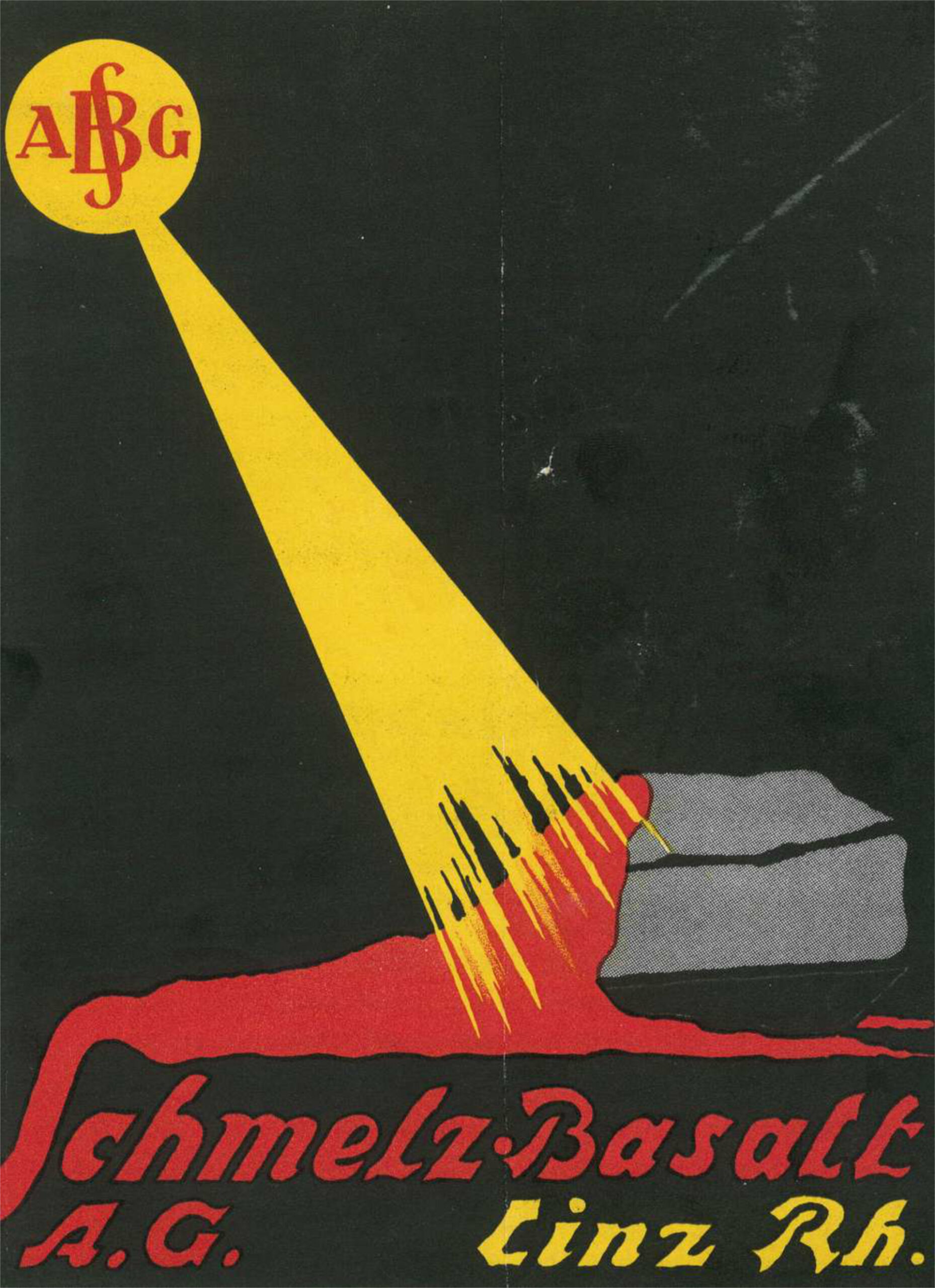

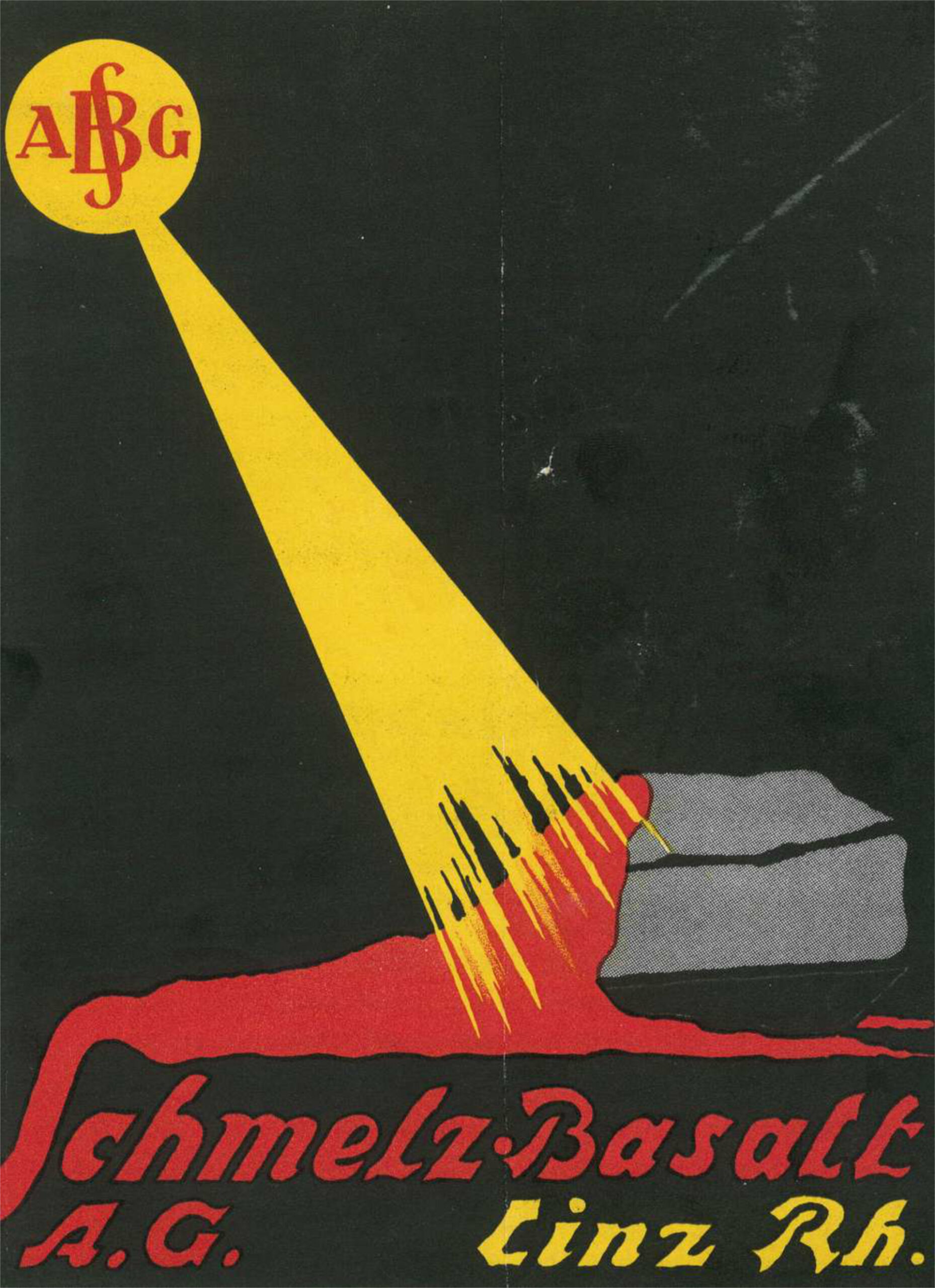

First brochure Schmelzbasalt

1921: The company is founded

On 7 September, Schmelzbasalt AG is founded in Linz am Rhein, a joint venture formed by the Compagnie Générale du Basalte and Basalt AG.

The aim is to produce fused cast basalt from the deposits in Vettelschoss in the Prussian Rhine Province and follow the French example by using it as an insulation material.

Representative buildings are built by architects Mattar & Scheler.

1921

First brochure Schmelzbasalt

Office and residential house of the Schmelzbasaltwerk in Kalenborn

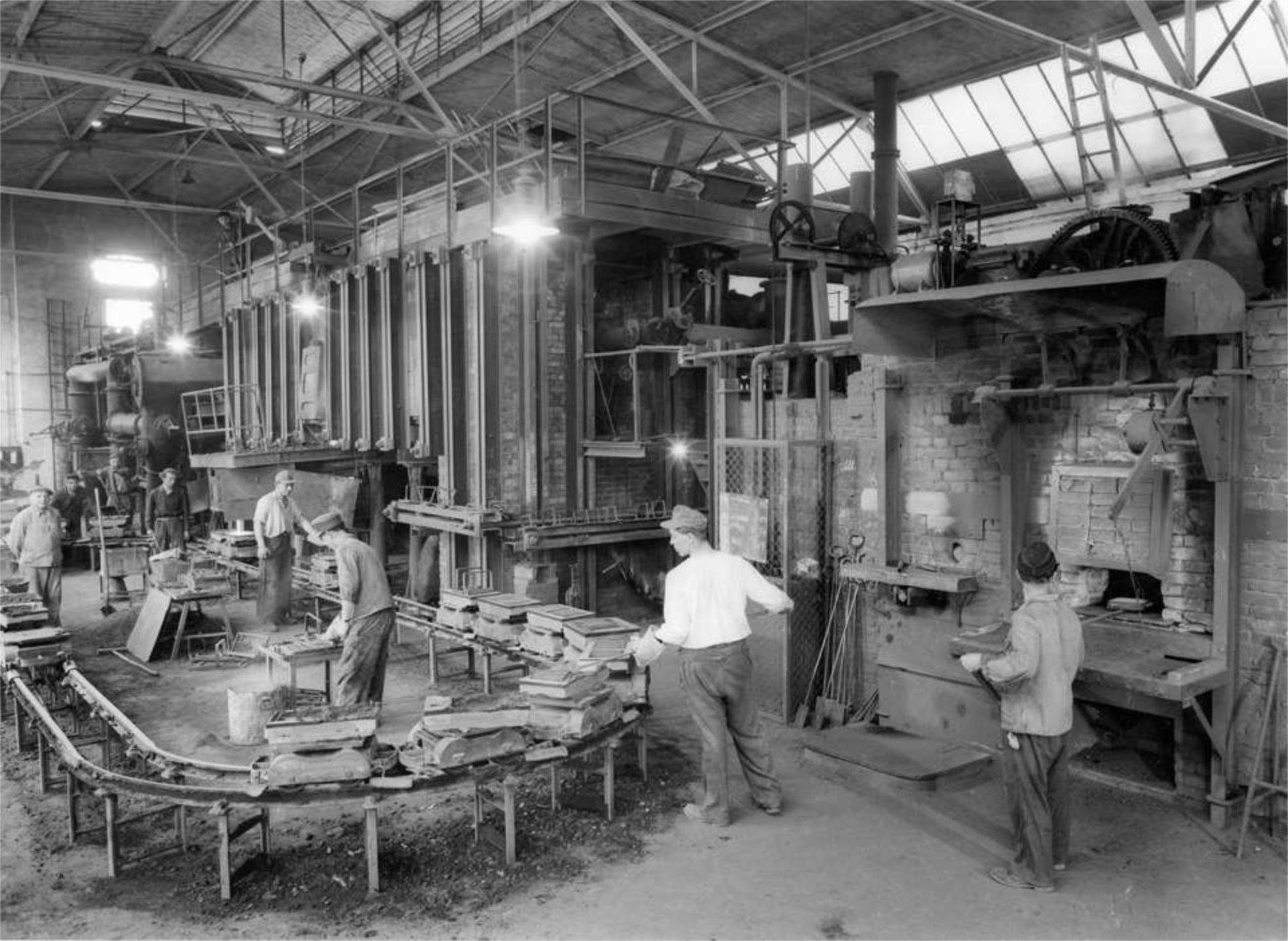

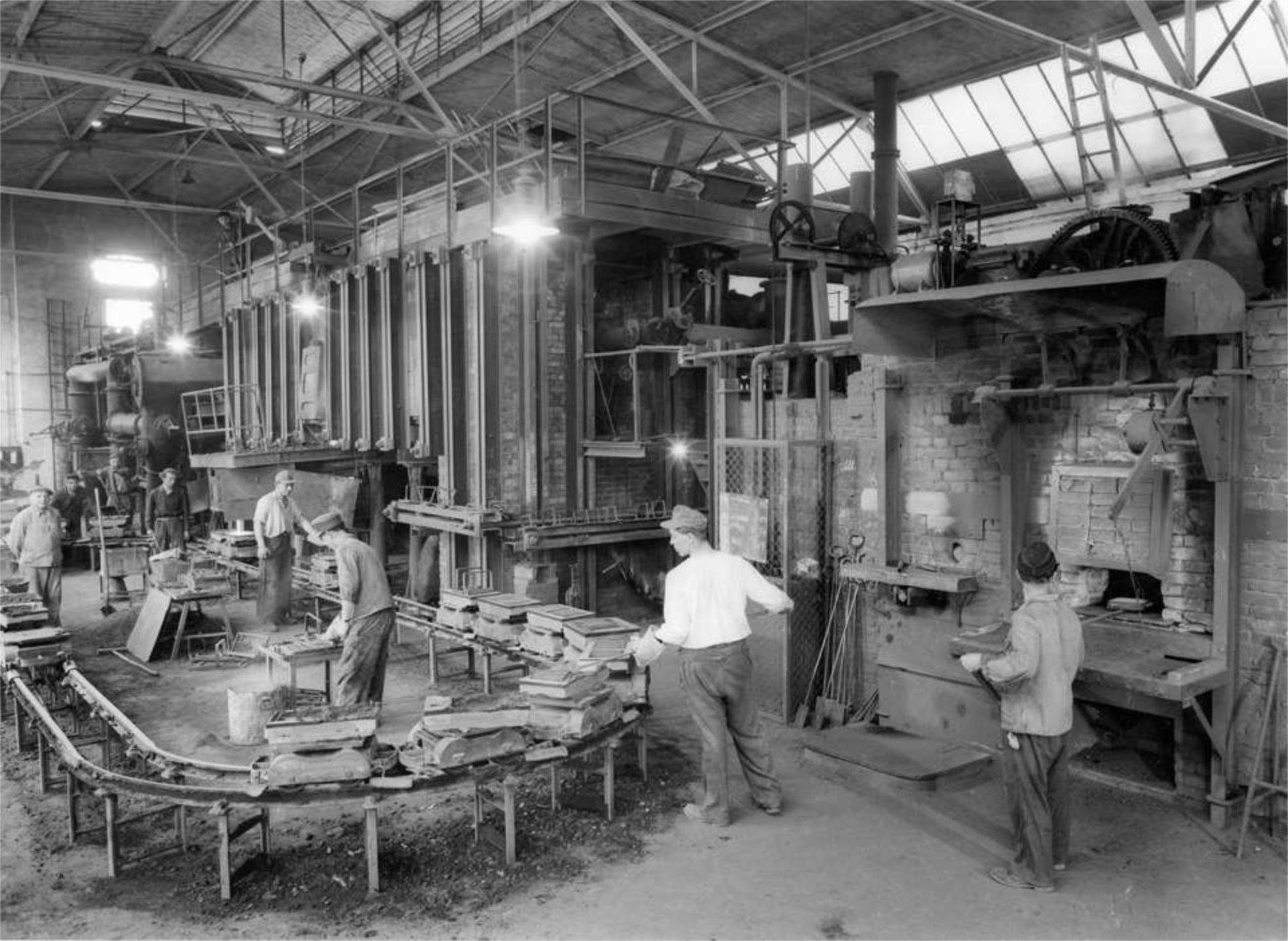

1924: Production starts in Vettelschoss

The early years are a little sluggish. The new material is different from the French material that had been successfully used as insulation when building the Paris metro. This is because the raw basalt comes from another source and has a different chemical composition.

1924

Office and residential house of the Schmelzbasaltwerk in Kalenborn

The company looks for new markets and improves the production processes, but it will still be many years before it begins to be successful.

1929: Production is halted

Ongoing sales problems oome to a head with the stock market crash and the ensuing global crisis, leading to production being halted. Existing stock continues to be sold and the search for suitable markets continues. Attempts are also made to establish fused cast basalt as a means of corrosion protection in the chemical industry.

1929

1935: A change of direction

Four new shareholders come together on 19 June 1935 to lease the Schmelzbasalt AG works. They focus their marketing efforts on industrial wear protection, but sales are still sluggish. After a few months, production is halted once again.

1935

Dr. Ing. Kurt Mauritz

1937: A new start

Two of the four shareholders leave the company. The other two change the company's name to Schmelzbasaltwerk Kalenborn – Dr. Ing. Mauritz Kommanditgesellschaft. Dr. Kurt Mauritz takes over as partner with unlimited liability – the grandfather of Dr. Conrad Mauritz, one of the current directors.

1937

Dr. Ing. Kurt Mauritz

1939: Business takes off

The company acquires customers in the coal mining and iron and steel industries. Kalenborn's fused cast basalt ABRESIST becomes increasingly popular as a material for industrial wear protection. Like many other companies at the time, Kalenborn is boosted by the war economy.

1939

1940: A valuable material

The armaments industry eats up all the iron and steel resources. Many industries seek a replacement in fused cast basalt, for example in the coal and potash mines, the ore mining industry, coking plants and the increasingly important hydrogenation plants, where synthetic petrol is produced. In order to meet the growing demand, Kalenborn installs a smelting furnace that operates 3 shifts and has a monthly capacity of 600 tonnes.

1940

1942: Leaseholders become owners

Mauritz KG buys the Schmelzbasalt AG works.

1942

1945: End of the war = end of production

In March the works comes under artillery fire during the battle to cross the Rhine at Remagen. Production is halted and it is a year before it can be started up again.

1945

1946: Hard times

Production restarts under difficult conditions. Times are hard, but the factory gives people hope. The workers are bound together by a sense of solidarity and the company develops a spirit of improvisation and energy that still permeates the company's culture today.

1946

1950s: The road to Europe

The sales operation is expanded by opening 15 agencies around Western Europe. By the end of the 1950s, exports account for 35% of total sales and pre-war production levels are once again achieved.

1950er

1960s: A global market

In the 1960s the sales operation is expanded to the USA, India and Australia.

1960er

1969: Expansion of R&D

The company's expertise in the production of fused cast basalt is extended to other materials. Intensive research is carried out into metal, ceramic and thermoplastic materials.

1969

Dipl.-Ing. Wonter Mauritz

1970: A new generation

Dr Kurt Mauritz dies. His son, Wonter Mauritz, takes over as Managing Partner.

His vision is to establish Kalenborn's global reputation as the experts in wear-resistant materials.

1970

Dipl.-Ing. Wonter Mauritz

1974: 50 years of basalt

Kalenborn celebrates the 50th anniversary of starting basalt production.

1974

1976: New synthetic products

The thriving new business in synthetic linings to promote material flow is expanded. Various thermoplastics such as PE, PP and PVC are sold around the world under the brand name KALEN.

1976

1977: Expansion to the USA

The Abresist Corporation is set up in Urbana, Indiana as an assembly plant for the American market. The US operation is strengthened stlll further with a bigger sales operation and a team of technical consultants.

1977

1980s: Ceramics

The range of materials is expanded with the introduction of ceramic wear protection in the form of KALOCER aluminum Oxide, KALCOR Zirconium Oxide and KALSICA Silicon Carbide.

1980er

1990s: Globalisation

1996 Kalenborn Delma, Poland - acquired

2000 Kalenborn Bazalt, Poland - acquired

2002 Kalenborn Canada - acquired

2002 Kalenborn do Brasil - founded

2003 Kalenborn Asia, Singapore - founded

2006 Kalenborn Refmon, Hungary - acquired

2007 Kalenborn OSW, Poland - acquired

2007 Kalenborn Weartech, Philippines - founded

2009 Kalenborn France - founded

1996

2014: Kalenborn as a global brand

The global network of companies brings together all its services under one brand name: Kalenborn. This provides a consistent way of telling the world how it is a leading, innovative and global full-service provider of top-quality wear prevention solutions.

2014

Inspection of joints and wear testing

2016: Expansion of research and development

Kalenborn is expanding its own research labs. In conjunction with recognised institutions and universities, along with ministry support, conventional materials testing is performed in compliance with international standards.

2016

Inspection of joints and wear testing

Vietnam Office

2018: Establishment of Vietnam office

After decades of successful collaboration with local plant and equipment manufacturers, the company’s own presence in the market further develops market potentials.

2018

Vietnam Office

New KALCRET materials

The addition of variants optimized for wear and cost complement the compound materials group, thereby satisfying customer requirements and making the range even more competitive.

2018

2019: Establishment of Kalenborn Polska

Merger of Kalenborn Bazalt and Kalenborn Delma under one roof in Poland. Bundling of sales forces to meet market needs in all product groups. Expansion of production and logistics capacities for the metallic materials group.

2019

2020: Expansion of production at Kalenborn Brazil

Development of the pipe systems product groups with the addition of its own pipe component production and expansion of KALIMPACT production with new machines. The greater manufacturing depth and quality improvements in these two product ranges will further enhance customer satisfaction and positioning on the market.

2020

2021